There are many problems that routinely affect warehouse operations. In this article, we show you 5 warehouse management solutions to solve those issues.

1. Warehouse Inventory Inaccuracy

One of the issues for businesses who deal with inventory is keeping up with accuracy. Accuracy and efficiency in handling inventory in warehousing go hand in hand. Inventory inaccuracy may arise from a number of reasons. The most common reason is human error. Initial counts, regular inventory counts or errors in everyday order picking can create significant discrepancies in the count in your inventory management system compared to on-hand inventory.

To solve this problem, business owners can train every warehouse worker intensively or encourage a strong working knowledge of how the system operates. This may help ensure the accuracy of the system.

Additionally, the technology employed in managing inventory in a warehouse is critical. Businesses can select a warehouse inventory management that provides RFID – Radio Frequency Identification based cycle counting in order to remain updated on inventory status. A barcode inventory system does that with ease.

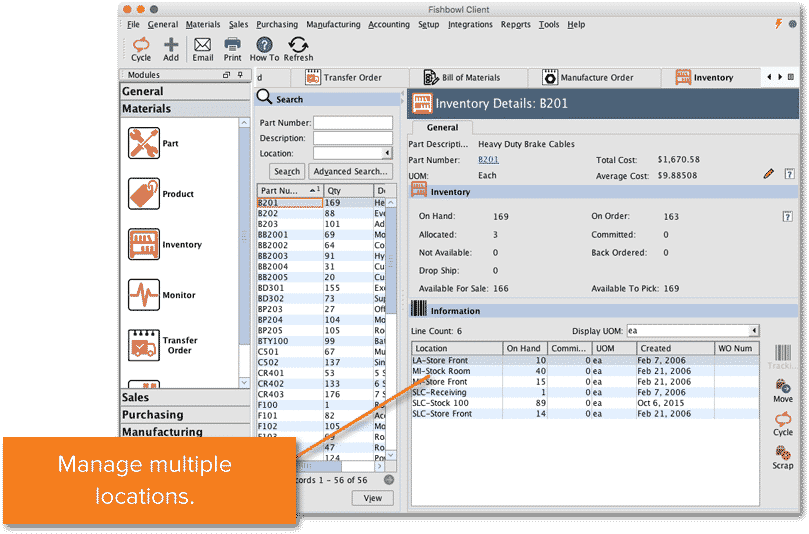

WMS solutions allow users to track inventory within a single warehouse or multiple locations

WMS solutions allow users to track inventory within a single warehouse or multiple locations

2. Inventory Location

New products are added to the inventory and space availability begins to impose more limits. Over time it caused inventory location problems. Failing to set up an efficient inventory location system can slow operations to a significant degree, leading to a variety of supply and delivery issues. Inventory Location is directly connected to the efficiency and operating cost of the warehouse. Setting up the inventory location requires you to define areas and spaces meant for specific purposes. You need to define warehouse numbers, the storage types, storage bin, etc.

With a warehouse management solution, the configuration and the workflow will go as you have intended to. If you have multiple warehouses spread across different geographical locations you may start with an inventory group, set up inventory locations and then allocate inventory area. Re-organizing the layout and ensuring easy access to most popular items can help to keep goods flowing efficiently throughout the workday.

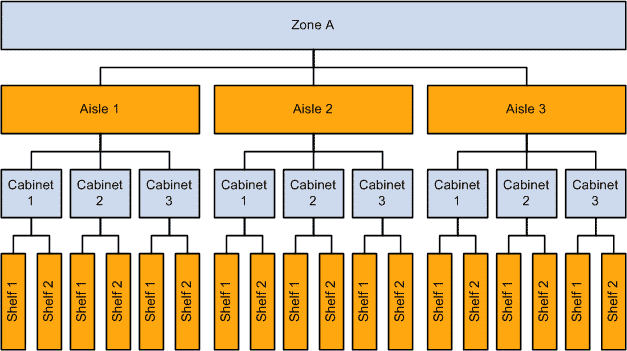

The hierarchical relationship between material storage locations, storage areas, and levels.

The hierarchical relationship between material storage locations, storage areas, and levels.

3. Picking Optimization

Picking is one of the most important tasks in each and every warehouse. A large part of the activity in warehouses is workers moving from one location to another to pick items and dispatch for shipping. But the issue is Picking is where the majority of management problems occur. A warehouse management software can help you increase picking productivity by facilitating batch and wave picking. Batch and Wave picking are based on SKUs – Stock Keeping Unit codes of the product and a Warehouse Management System can easily create a record of that.

4. Warehouse Layout

Efficient use of space is a critical factor in warehousing. Inadequate storage space and inefficient use of available storage are common problems in warehouses with poor facility layout. Poorly configured warehouses can have negative impacts on profits. Besides, space utilization within a warehouse is directly connected to the movement time of pickers.

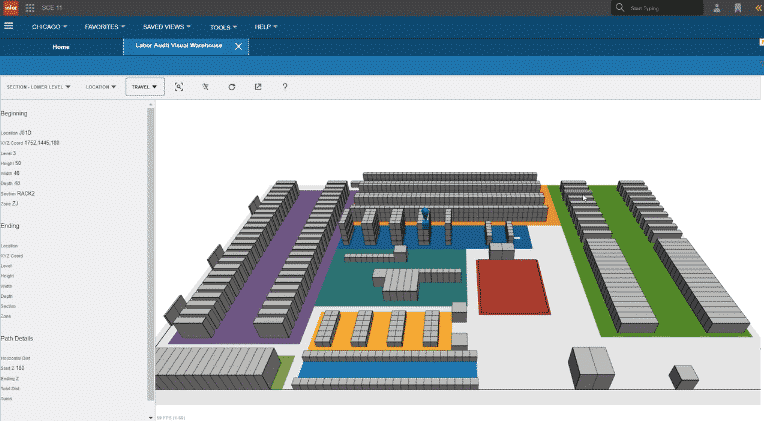

Warehouse simulators help identify potential issues and create workflows

Warehouse simulators help identify potential issues and create workflows

Business owners can use both the floor space and the vertical space available. Using forklifts that reach the roof of the warehouse allows for a configuration that maximizes both the horizontal and vertical space. In addition, using a warehouse management solution can help you have a quick insight into your fast-selling items. You can put the fast-selling items at a place where it is easier to pick, pack and ship them leading to lower travel time and costs. Once, you sort your inventory with respect to the SKUs, you may put the slow-selling items farther into the warehouse, or up in the higher rack space.

5. High Labor Costs

Inbound Logistics estimates that labor constitutes about 65% of the operating budgets of most warehouses. A typical warehouse uses expensive equipment and employs a large labor force, presenting a challenge that is for the most part unique to warehousing operations.

To solve this issue, businesses can use Warehouse Management Software to streamline different business processes and determine the most effective way to utilize workforce, space, inventory, and machinery. With the help of warehouse management solution, you can identify the expiring and perishable items and have them picked first for delivery. This optimizes the picking and putting-away efforts, which reduces overall waste and results in considerable savings over a period of time.

Innotech Viet Nam Corporation is a software outsourcing company focusing on high-quality services in Viet Nam. At Innotech Vietnam, We strive for the creation, innovation, development, and advanced solutions. We provide a wide range of software services to meet all requirements and expectations from customers. We turn these advanced technologies into value for our customers through our professional solutions and business service worldwide.

Contact experts at Innotech Vietnam for any questions about Software outsourcing development questions!

Email: [email protected]