According to statistics, 58% of warehouse managers in Vietnamese enterprises have planned since 2023 to implement RFID technology in warehouse management system and logistics (Source: VietnamNet). Why is that? The following article will explain the essence of this technology and how it can be successfully applied in businesses.

1. What is RFID technology?

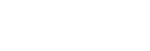

RFID technology (Radio Frequency Identification) is a system that uses radio waves to automatically identify information and objects such as goods, containers, or pallets that have been tagged. From a distance and without physical contact, RFID technology can read tag information and integrate data without the need for direct physical interaction between objects.

What is RFID?

1.1. Characteristics of RFID technology

- Contactless automatic identification: RFID uses radio waves to read/write data without physical contact like barcodes, allowing staff to scan dozens of items at the same time.

- Data reading/writing capability: With this technology, data from scanned items is instantly available on the computer system thanks to RFID’s excellent ability to record and consolidate information.

- Flexible reading distance: With passive tags, the reading range is within about 20 cm. However, if active tags are used, the reading distance can extend to several meters, making remote integration much more convenient.

Characteristics of RFID make it excellent to use

- Easy integration with management systems: RFID works effectively when combined with warehouse management software (WMS), ERP, SCM, etc., making it easier to track and trace the quantity, quality, or journey of goods.

- Data encryption and security: The ability to encrypt and secure data within RFID tags ensures absolute protection of product information and critical business data, preventing any unauthorized copying or data theft.

1.2. Components of RFID technology

RFID systems consist of two main components: hardware and software.

a. RFID Hardware:

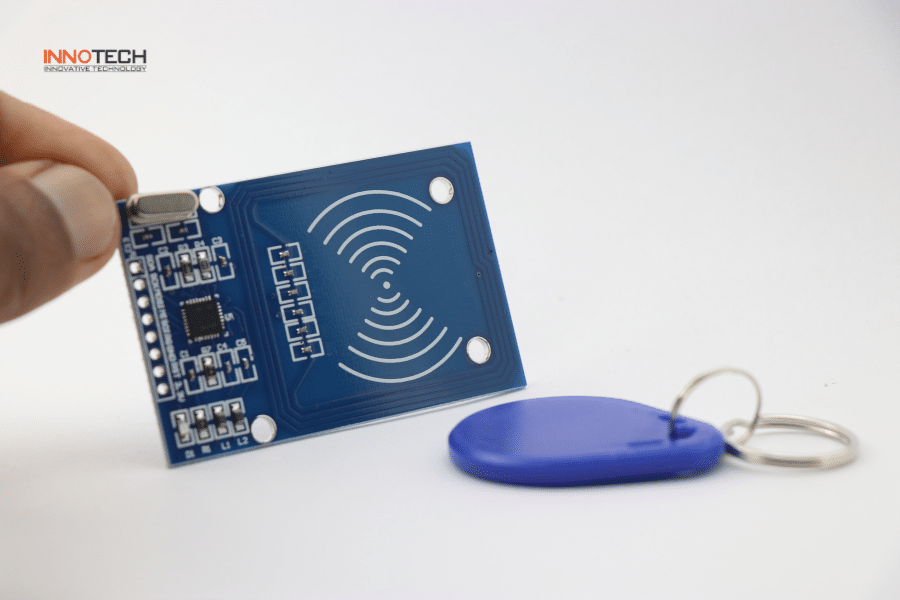

- RFID Tags: Electronically programmed with a chip to store product identification data, enclosed in protective materials such as paper, plastic, or metal.

- RFID Reader: The device that receives information signals from the tags. It consists of one or more antennas that emit radio waves. After capturing data from the tagged object, the reader sends the electronic information to the company’s integrated system.

- RFID Antenna: Captures signals from goods.

- Server: Connects to the installed system to process the information collected from products.

- RFID Printer: Used to print labels that can be read both physically and intelligently, embedding product data such as ID, serial number, and warehouse location.

b. RFID Software:

- Supporting software (ERP, MES, PLM, SCM): RFID can be integrated with enterprise management systems such as ERP, MES, PLM, and SCM, enabling the collected data to support more effective and rational business decision-making.

1.3. Operating principle of RFID technology

After the objects to be managed are equipped with an integrated chip, a reader installed at a specific location will emit radio waves to collect product information and transmit it to the system.

When the RFID tag enters the radio frequency field emitted by the RFID reader, it will receive the electromagnetic signal, capture it, and transmit back its identification code to the reader. In this way, the RFID reader can identify which RFID tag is within its operating range.

>>> Learn more about RFID software development services in warehouse management.

1.4. How is RFID applied in enterprises?

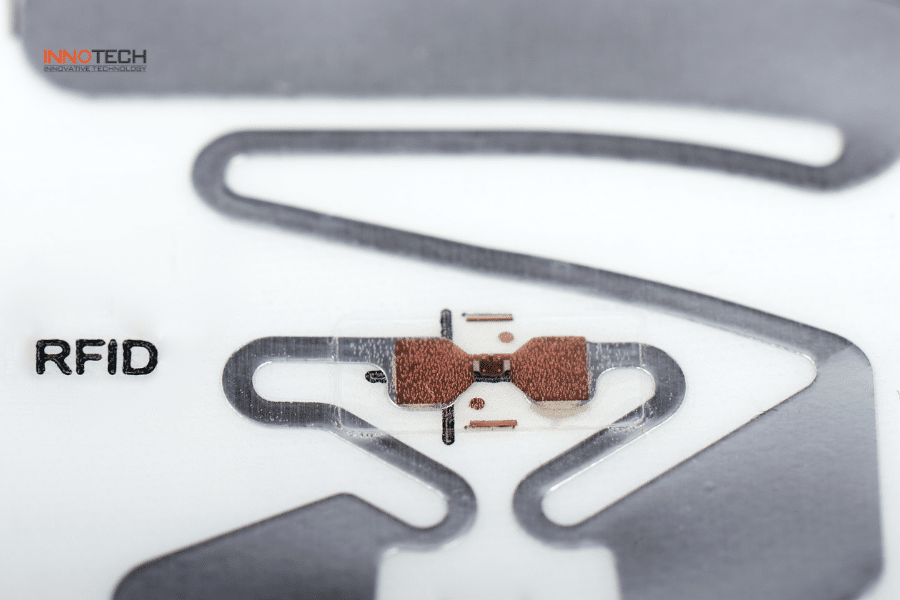

Currently, RFID technology is applied to various activities such as RFID in warehouse management, logistics, and production.

- RFID in Warehouse Management: Enterprises attach RFID tags to goods, pallets, and containers. During warehouse inbound or outbound operations, RFID readers can scan the entire area and record product data without the need to scan each item individually.

- RFID in Supply Chain Management: By monitoring the arrival and departure times of containers and packages at transportation points, RFID can accurately track the location and assess the condition of goods throughout the shipping process.

Enterprises have applied RFID in warehouse management system, supply chain, production, and more.

- RFID in Production Management: The product lifecycle—including maintenance, repair, and servicing—as well as components such as raw materials, equipment, and semi-finished goods, are tracked throughout the production process to prevent losses and delays in task execution.

- RFID in Enterprise Asset Management: The location, condition, usage history, and maintenance schedules of assets can be accurately reported by attaching RFID tags to machinery, equipment, and fixed assets.

In addition, RFID technology is also applied in other areas such as human resource and security management, retail, and enhancing customer experience.

2. Apply RFID technology in warehouse management and logistic

With its superior features, RFID technology in warehouse management and logistics operations is widely applied, delivering outstanding efficiency for many businesses.

2.1. How is RFID technology in warehouse management applied?

-

Inventory Management

Add inventory items to orders through code scanning, simplifying the process. The system also enables efficient categorization and management of your documents.

-

Barcode Scanning Function

Scan barcodes to add items to orders, generate barcodes for documents, and search for goods or documents by scanning codes.

-

Areas and Locations

Regardless of the type of location or where goods are stored, RFID technology supports organizing and managing inventory data scientifically by area and location.

-

Purchase Orders

Integrating purchase orders makes it easier to replenish inventory by placing new orders and tracking when new items will arrive.

-

Financial Reports

Generate detailed reports on inventory, sales, and services. Filter reports by time period and category to identify the most profitable items.

>> Learn more about integrating smart AI in inventory management.

2.2. How is RFID technology in logistics operations applied?

a. Tracking goods during transportation

When each package, pallet, or container is tagged with RFID, readers placed at control points such as warehouse gates, truck stations, and transit hubs automatically record the time, location, and transportation status of the goods without requiring vehicles to stop or goods to be unloaded.

RFID in logistics brings many benefits to businesses.

b. Automating Warehouse Inbound – Outbound processes

When a truck enters the warehouse, the RFID system automatically records inbound and outbound goods without manual inspection, minimizing the need for unloading. Immediately afterward, the data is synchronized with the management system. The quantity and types of goods are strictly monitored, reducing errors in the import/export process.

2.3. Companies providing RFID technology solutions for warehouse and logistics management

If you are looking for a reputable company that provides effective technology solutions, Innotech will be your ideal choice. Innotech has a team of highly skilled professionals in designing and applying RFID technology in warehouse and logistics management. With Innotech’s RFID warehouse management software, you will receive:

- An intuitive dashboard that accurately displays inventory, pending orders, and orders ready for dispatch.

- Automatic order grouping and picking based on the FIFO principle, avoiding old stock and saving labor.

- A detailed picking list showing product information and warehouse locations, sent directly to employees’ mobile devices.

- RFID-based picking with one-touch scanning, product-by-product verification, and real-time progress tracking.

- Automated classification with RFID scanning, indicator lights guiding workers to the correct container, and automatic logging for anytime review.

Innotech provides cutting-edge RFID technology for warehouse management system and logistic.

Why should you choose Innotech’s RFID Warehouse Management solution?

- Absolutely accurate inventory data

- Picking and sorting processes many times faster

- Low investment cost and rapid implementation time

- Flexible integration and easy data synchronization with ERP, POS, and accounting systems

- Customizable features tailored to your company’s unique processes

Leave your information here to receive expert consultation!

The above provides an overview of RFID technology and how RFID in warehouse and logistics management is applied. From here, businesses can identify effective solutions to minimize costs and maximize labor efficiency.